|

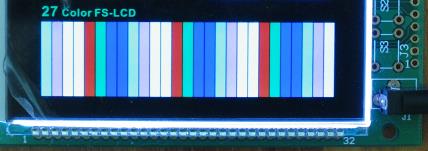

For standard product spec please check in The Liquid Crystal Display Module (LCM) products we built are widely applied in the personal electronic end products, the household appliances, the industrial and/or the commercial equipment and instrument, the handheld gadget and telephone, etc.. Our products include Alphanumeric (segment) LCM, Character dot-matrix LCM, and Graphics dot matrix LCM, small-middle TFT LCM. We have the standard series and the customized series, of which is upon the customer’s request. Our engineers in electronic circuit design, in the module structure and in the test software are stand-by for serving you and satisfying you. Tell us your requirement, or fill in the Check-list for Custom Design LCMs the specification you want. |

|

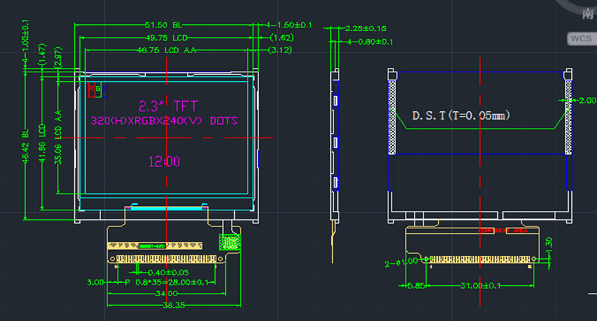

The business procedures: Make a deal with us 1 Discuss and exchange the specification, drawing 1.1 If you don’t know more the spec about the LCD/LCM, we’ll prepare one spec checklist for you and send you, after you preliminarily accept the initial quotation and the terms. 1.2 You need to let us know below the basic info for the spec/darwing: 1.2.1 The application, applying in what kind of industry or equipment? 1.2.2 The LCM and/ or the LCD outline size, the viewing area size. The installing size of the holes in the PCB, if it’s in COB 1.2.3 The range of viewing angle? TN, HTN, STN or TFT? The dot matrix number and lines, if not an alphanumeric. 1.2.4 The display mode, positive or negative; or the colors of the background, and the character/ dot displayed. 1.2.5 Specifying the driver /controller IC, model number and the packaging way, in COB(chip on PCBoard), COG(chip on glass), or TAB. 1.2.6 Connecting ways for LCD and for the module; 1.2.7 Spec of the backlight? LED qty and color? FPC length and the connecting way, soldering or connector, etc.. 2 Issue an official quotation and negotiate the price level 2.1 Tooling charge, if customized, if applicable, 2.2 Quotation based on the quantity and the lot size. 3 Sample making, if applicable 3.1 Pay tooling charge, and/or sampling fee, if applicable; 3.2 For customized LCD/LCM, drawing needs 3~5 days; 3.3 Drawing checking and approval by customer; 3.4 The lead time for the tooling/sampling is 10~20 days, excluding the shipping duration. 4 Sample delivering and verifying/test 5 Sample discussing, engineering change request, Finalizing /confirming sample and approving drawing/ specification 6 First lot production, the lead time for 500~2,000pcs is about 3~4 weeks 6.1 Pay deposit, 40% for standard product, or 70% for customized specification. 6.2 Manufacturing the products. 6.3 Inform the finish, assign the shipping company and the date. 6.4 Show the picture of the products, pay the remainder 60% or 30% before shipping out. |

|

Cell (86) 136 0307 7736;Tel:(86) 755 2959 0288; Fax:(86) 755 2959 0098; sale2@hooh.us; Skype: armandhooh; |

|

HOOH LCD Module Encoding Method Version: 20111031 1 H means HOOH LTD; 2 M=Monochrome LCD Module, T=TFT module; 3 Driving and/or controller IC mounting way. H M B 24 64 A 6- b L 2 W H T 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 G – COG chip on glass; N – Without IC; B– COB chip on board, die bonding; T –TAB TCP;S—SMT; 4&5 LCD OF FUNCTION 24 means 240; Characters model: Number of characters per line;Graphic model: Number of dots each line; For alphanumeric: 24 pins mark 24p, 6 pins mark 6p; R=rubber zebra connection, P=FPC connection; H=heat sealing connector 6&7 LCD OF FUNCTION: Characters model: Number of character lines; Graphic model: Number of row dots;For alphanumeric, marks duty. 1/6 marks 6, static marks 1; 1/24 marks 24; 8 VERSION:Letter or number, include spec such as: speciality,controller model, PCB version, outline size, bezel size, viewing area etc.. 9.1 For monochrome LCD, B-black mask black background; T-TN; H-HTN; STN,VIEWING ANGLE: X –Upper XII 12 o’ clock;6 –Down 6 o’ clock;3 –Right 3 o’ clock;9 – Left 9 o’ clock;T – Others; 9.2 For TFT LCD, 035, means the panel size is 3.5 inch in diagonal. |

|

10 LCD MODE: Positive: F-FSTN; G–STN Grey;Y –STN Yellow green; For transmissive or reflective polarizer, default no code; For transflective, adding code F. Negative: n-TN; b–STN Blue; f-FSTN; C-Color STN; t – Negative / Tranflective; m – Negative / Transmissive; O-OLED; T-TFT; H M B 24 64 A 6- b L 2 W H T 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 11 BACKLIGHT MODE: Without backlight : R – Reflective;T – Transflective; M– Transmissive; Blacklight: L – LED (Transflective) edge-lit led with edge PCB; B-means bottom-mounted led; S-side lit led with bottom PCB; C – CCFL (Transmissive);E – EL (Transflective); 12 Quantity of LED; 13 BACKLIGHT COLOR B – Blue, A – Amber, Y – Yellow green, R– Red, W–White, N – Without backlight 14 For dot matrix LCM, the connecting way of the module: P=FPC; F=FFC; H=header in female; M=leads; If soldering pad, no mark. 15 SPECIAL REMARKS: T – Wi th touch panel |