|

We provide the service of design and mold making and plastic injection molding in our allied facilities in Dongguan and Shenzhen. We are one of the few allied firms that can provide the solution for a plastic part project which include all the processes: Product Engineering Design Service: part/sculpture 3D-scan and drawing, revise model per comment, product engineering; Mold design: Design the mold, CAD mold splitting/programming, CNC and cutter path programming; Mold making: Electrode making, EDM, wire cut and CNC tooling, etc.. Try out and first shot; First Shot Reviewing and Trimming: reviewing, discussion, confirmation, debug, mold modification, mold polishing; Pilot-run and Contract Manufacturing Service: Engineering pilot-run, production pilot-run and mass molding production. Also, upon request service for one of the, or some of the above-mentioned processes are welcome. Some of our clients email us the approved final plastic part drawing, 2D or 3D drawing, we design and build the mold per customer’s part drawing, then we ship the mold to the location where our clients assigned. Of course, we can make mold per customer’s mold design drawing and ship out the mold. According to our experience, in some cases our clients assign the mold splitting scheme; and, in some cases, we discuss the mold splitting scheme with our clients,then determine the scheme. Lead-time: It is various. It depends on the project and the complexity of the mold. From receiving (for copying a matured mold), or from finalizing (for creating a new mold) a mold design drawing file to the first shot, normally the duration is 5-6 weeks; The F/S reviewing, debug, trimming and polishing normally takes about another 10 days-2 weeks, if there is no other modification on the plastic part. Quality steel and mold parts: We do guarantee using only quality steel imported from Germany, Swiss and Japan for making mold core and cavity/ies. We use only quality mold parts such as mold base, hot runner and spring, etc. which buying from reputable suppliers. |

|

HOOH LTD. Quality Product, Quality Service |

|

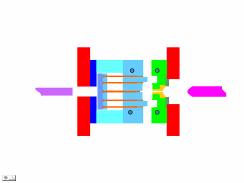

Plastic Part, Mold Making and Injection Molding Customers’ requirement is the opportunity of our business. Many of our customers require a much better result in even and uniformity in the backlight. And, some of our customers require an advance installation way in the backlight, such as with fasteners /hook or ears with installing holes, etc. in the LGP (light guide plate). That requires a plastic injection molding (PIM) LGP in the backlight. Some of our customers require plastic parts, for enclosure, housing, etc. Some of our customers require the turnkey project and the solution. So that we have developed the service on plastic mold and molding. |