|

LCM Catalog Touch Panel LCM Spec Checklist LED Backlight |

|

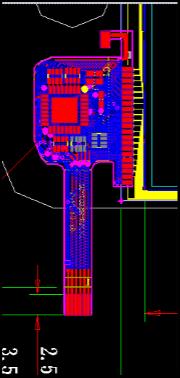

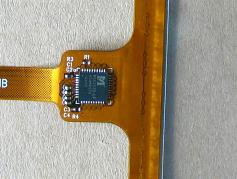

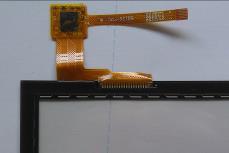

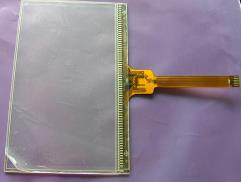

Basic knowledge of Capacitive Touch Screen There are some different processing and different parts/configurations for capacitive touch screen. The customer needs to be known and choose the right things. Basic parts of a CTS: Lens, sensor, FPC, IC, chip components on FPC. Lens is also the front panel, made of pre-straining (tempered) glass. Lens and sensor are bonded together by OCA, the optical clear adhesive. OCA is melt between lens and sensor by the equipment. Customer should send the front panel design drawing to us for a basic estimate and comment, for matching the sensor during pre-sampling. The sensor which has no bonded lens will be easily damaged and misfunction.

The right assembly processing for LCD+sensor+front panel is that, to do that in once, not twice.

Software adapting work should be done by the engineer of the IC supplier. So, if it’s applicable, it is strongly recommended that, our customer ship their final product, all the assembly to us, for doing the software adapting work. Software adapting work only needs to be done during sampling, no need to do that in mass production.

Between sensor and lens, there is only one processing: OCA bonding.

Between the CTS and the LCD, there are two processing: Frame attaching, and OCA-all-joint- bonding. Our customer might be able to do the frame attaching, and it is not recommended that customer do OCA-all-joint-bonding. Please be reminded again that, above means between the LCD and CTS, not between the lens and sensor. I meant, customer MUST send the front panel to us for bonding with sensor. Sensor and lens (front panel ) should not be split.

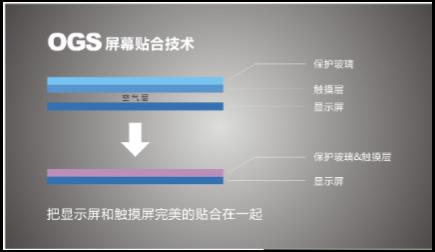

Recent years the OGS are booming. OGS, mean one glass solution, sensor ITO circuit is in the Lens, sensor and lens are in only one layer of glass.

Below show the comparison between the OGS and the non-OGS. The above is non-OGS, front panel+sensor+air space+ LCD. The bottom is the OGS, CTS is only one layer of glass, no air space,

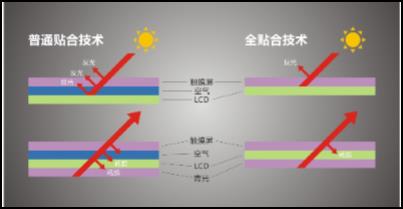

Below the left is the frame attaching, the right is the OCA-all-joint-bonding. The top is with backlight, the bottom is without backlight. Below the top show the glisten situation. The bottom show the wear off, or

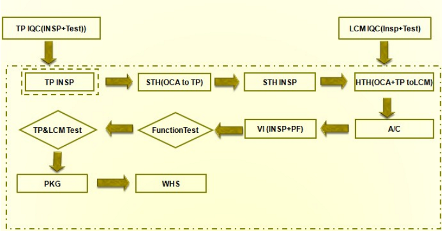

Below is the basic flow chart of the OCA-all-joint-bonding processing:

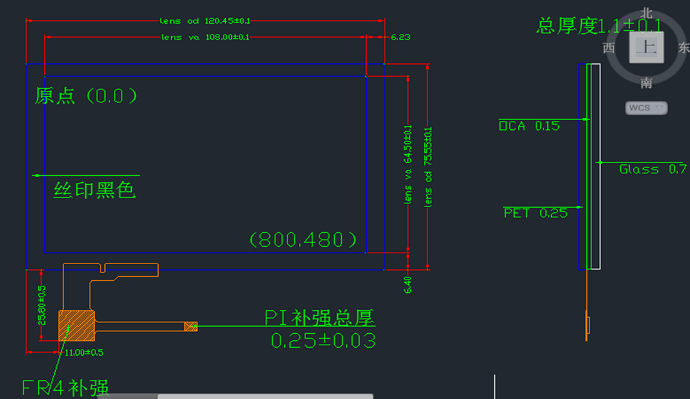

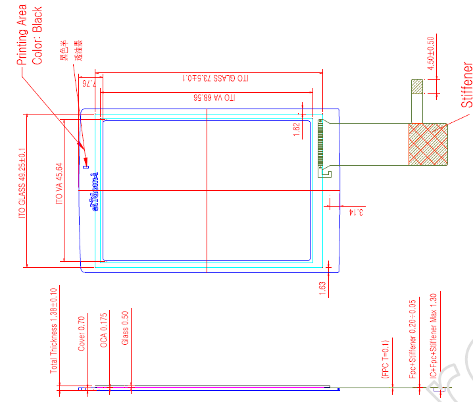

G+G(Glass+Glass),0.7mm(Cover Lens)+0.175mm(OCA)+0.5mm(Glass sensor) total thickness of CTS:1.375mm

G+F(Glass+Film):0.7mm(Cover Lens)+0.175mm(OCA)+0.125mm(Film sensor)+0.05mm(OCA)+0.125mm(Film)Total thickness of CTS:1.175mm

OGS (one glass solution): 0.7mm, total CTS thickness is only 0.7mm.

Then, Do you want an OGS or G+G structure? Do you want a frame bonding or an OCA all-joint bonding? Do you want to design the front glass (the lens ) by yourself? If yes, please send me the lens drawing.

|